Good Flowability High Strength Low Shrinkage RTV-2 Liquid Platinum

Cure Silicone Rubber For Making Candy Fondant Molds

Product description

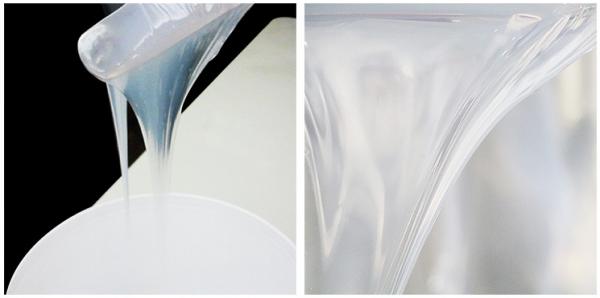

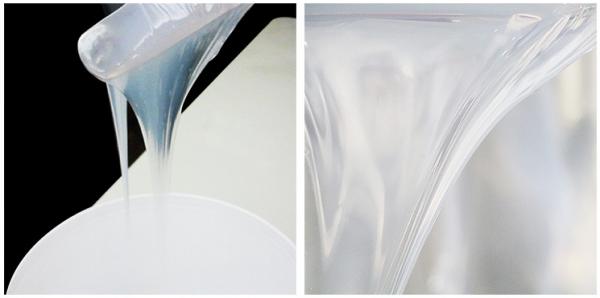

Two-component addition type silicone rubber Silicone Rubber is a two-part, platinum-catalyzed, liquid silicone

system that cures (RTV) to a Shore A20 rubber. The polymerization can be accelerated by heat. The silicone

components are delivered as liquids, which once mixed and cured

transform into a transparent, elastic and resistant material.

Polymerization occurs without formation of heat.

Platinum cure silicone rubber, also called addition cure silicone,

are two-component high tear strength and flexible mold or casting

compounds. They are recommended as a mold material for casting

polyurethane, epoxy, or polyester resins, wax and a wide range of

other casting materials. They exhibit extremely low shrinkage and

high physical properties. These rubbers are chemically sensitive to

latex, sulfur, and certain other materials. Platinum cure silicone

can also be used to cast prosthetics for special effects makeup and

medical training devices.

Applications

Label manufacturing, Molding applications requiring low shrinkage

e.g., jewelry, automotive, plaster, cement, cake decorations, etc.

Features

Two-part platinum-cured (addition-cure) silicone rubbers

Room temperature curing (RTV)

Shore Hardness Options: A10-A60

Do not exhibit shrinkage upon curing so they are useful for casting

dimensionally stable parts for highly accurate prototyping and

model making applications

Molds do not require release agents when casting most materials

Cured molds have a long library life

Pourable or brushable (thicken with thixo agent)

High-strength

Excellent chemical resistance

Reproduces fine details

Can be accelerated for rapid cure

Ideal for the most demanding resin casting applications

Technical Properties

| Item No. | MCPLA-L20A/B |

| Appearance | Viscous liquid |

| Color | Translucent |

| Viscosity ( cps,approx.) | 7000-9000 |

| Mix ratio (A:B) | 1:1 |

| Working time(at 25℃ ,minutes) | 30-40 |

| Curing time(at 25℃,hrs,approx.) | 6 |

| Hardness Shore A(after 24 h) | 20 |

| Tensile Strength(Mpa,after 24 h) | 3.8 |

| Elongation(%) | 600 |

| Tear Strength(N/mm) | 16 |

| Linear Shrinkage (%) | 0.1 |

Processing and Instructions of Addition Cure Silicones

1. Mixing the two components

According the mixing ration 10:1 or 1:1 weighting A and B, the two

components may be thoroughly mixed either by hand or using a

low-speed electric to minimize the degassing of bubbles and to

avoid any temperature increase. Note: It is also possible to use a

special mixing and dispensing machine for the silicone components,

further information is available upon request.

2. Moulding

The mixture should be degassed preferably at 30 to 50 mbar to

eliminate any entrapped air. If a dispensing machine is used, the

two components are degassed separately prior to mixing. The

silicone mixture expands to 3-4 times of its initial volume and

bubbles rise to the surface. The bubbles progressively disappear

and the mixture returns to its initial volume after 5 to 10

minutes. Wait a few minutes to complete the degassing and then

flash the vacuum. The silicone is ready for pouring, either by

gravity or under low pressure.

Note: Flashing the vacuum once or twice accelerates the degassing.

It is recommended to use a container with a high diameter/height

ratio (3 to 4 times of the initial volume)

3. Polymerisation

The curing may be slowed down at lower temperature or accelerated

by applying heat.

Note:

Contamination from sulfur (e.g., sulfur-based clay), amines, tin

compounds, cured polyester resin, some paints and some silicone

rubbers may inhibit surface cure of platinum-cured rubbers.

Apply a release agent, Although not usually necessary, a release

agent will make demolding easier when casting into most surfaces.

NOTE ON CURE INHIBITION: Sulfur/tin/amine-contaminated materials

and tools will cause cure inhibition in platinum-cured silicone

rubbers, which means that the rubber that is in contact with the

contaminated surface will remain gummy or uncured. Make sure to

test cure the rubber on your surface before full-scale application.

Use a polyurethane or tin-cured silicone rubber if you know that

you’ll be working with any of these inhibitors.

Packaging

20kg per drum, 200kg per drum

Storage and shelf life

MC Silicone MCPLA -H Series should be used within 12 months from

the manufacturing date. Beyond this date, MC silicone no longer

guarantees the products confirms with the sales Specification. In

order to preserve best properties it is recommended to follow

strictly the following guild lines:

Store the original packing tightly sealed and at a temperature

below 30 degree Celsius.

Use the product as soon as the packaging has been opened.